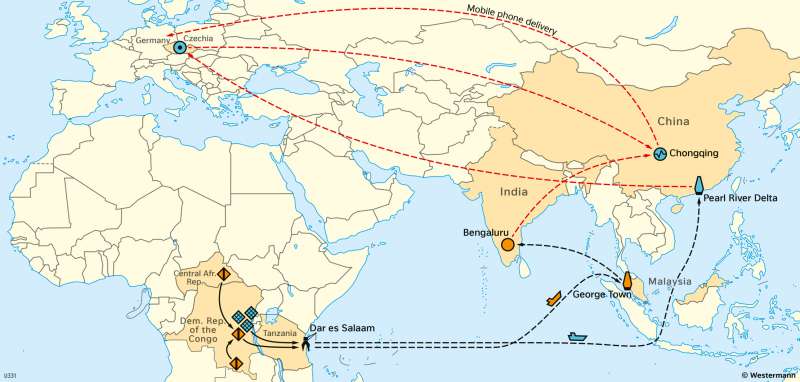

The World - Supply of minerals from Central Africa for the production of mobile phones

Economy

978-3-14-100890-6 | Page 151 | Ill. 2

Overview

About 60 different materials are processed in a mobile phone. These include plastics (50%), metals (25%), glass and ceramics (16%). The 30 or so metals used in mobile phones include copper (15%), iron (3%), aluminium (3%), nickel (2%), and tin (1%), as well as small amounts of silver, gold, and other metals (1%). With cobalt, gallium, indium, niobium, tantalum, tungsten and the platinum group metals, seven substances alone are among the critical or rare metals, whose deposits are becoming increasingly scarce worldwide. Tantalum is extracted from coltan, a mineral mixture that belongs to the ores. In addition, a mobile phone contains rare earths, which are used in very small quantities.

Coltan - raw material for mobile phones from the D. R. Congo

The D. R. Congo is one of the areas with the largest and most productive deposits of coltan. Many mines in eastern Congo are under the control of armed groups who finance their "war" in Congo with the proceeds from the sale of coltan (at least 5 million dead since 1995). In addition, there are about 10 million small-scale miners who extract coltan under extremely poor working conditions.

The production chain of a mobile phone

The map shows an example of a part of the production chain of a mobile phone, namely the further processing of the raw materials extracted in Congo for it. Coltan and tin from the D. R. Congo and coltan from the Central African Republic are shipped to Asia via the port of Dar es Salaam in Tanzania. Tantalum is then extracted from the coltan ore in China's Pearl River Delta and airfreighted to a capacitor factory in the Czech Republic. The finished capacitors, which are used to store electrical charges, are then flown back to China, to a mobile phone factory in Chongqing. The tin ore is shipped to Kuala Lumpur in Malaysia. Tin is extracted from it in a tin smelter. This is also transported by ship to a solder factory in Bangalore, India. Solder is a metal alloy (a mixture of lead, tin, zinc, silver, and copper produced by melting them together). The metal alloy is used to firmly connect the wire contacts of electronic components with the copper conductor tracks. The solder is also transported by plane to the mobile phone factory in Chongqing. There, mobile phones are produced from all the delivered components, which are then transported by plane to the countries where they are sold, such as Germany. About half of our mobile phones and smartphones are manufactured in China.

The production chain of a mobile phone

The map shows an example of a part of the production chain of a mobile phone, namely the further processing of the raw materials extracted in Congo for it. Coltan and tin from the D. R. Congo and coltan from the Central African Republic are shipped to Asia via the port of Dar es Salaam in Tanzania. Tantalum is then extracted from the coltan ore in China's Pearl River Delta and airfreighted to a capacitor factory in the Czech Republic. The finished capacitors, which are used to store electrical charges, are then flown back to China, to a mobile phone factory in Chongqing. The tin ore is shipped to Kuala Lumpur in Malaysia. Tin is extracted from it in a tin smelter. This is also transported by ship to a solder factory in Bangalore, India. Solder is a metal alloy (a mixture of lead, tin, zinc, silver, and copper produced by melting them together). The metal alloy is used to firmly connect the wire contacts of electronic components with the copper conductor tracks. The solder is also transported by plane to the mobile phone factory in Chongqing. There, mobile phones are produced from all the delivered components, which are then transported by plane to the countries where they are sold, such as Germany. About half of our mobile phones and smartphones are manufactured in China.